Labthink provides peel off strength tester for adhesives adhesive tapes pressure sensitive tapes medical adhesive bandage protection films release paper laminated films leatheroid woven bags and paper.

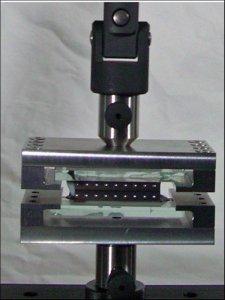

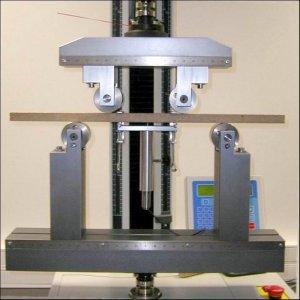

Peel strength test equipment.

The average load per unit width of bond line required to gradually separate a flexible member from a rigid member over adhered surfaces.

Peel strength testing is the average load per unit width of bond line required to separate bonded materials where the angle of separation is 180.

What makes peel testing unique are the many varieties of peel tests that can be performed using a universal test machine.

Common peel testing definitions and keywords include.

The angle between members varies with the type of peel test t peel 90 degree peel 180 degree peel floating roller or climbing drum.

The most common types of peel tests include the t peel 180 peel 90 peel peel wheel testing floating roller peel testing and climbing drum peel testing.

This type of peel thus tends to provide the lowest values of any peel test 6.

These steps can also be used when testing to astm d6252 for 90 degree label peel testing.

Peel testing is one way to characterize adhesive bonds.

With elastomeric adhesives peel strength is dependent on bond thickness.

In this test the entire load applied is transmitted to the bond.

Probably the most widely used peel test for thin gauge metal adherends is the t peel test astm d1876.

Labthink peel off strength tester can be used for 90 180 degree peel strength test and tensile test of applicable materials labthink peel off strength tester is controlled by micro.